Vertical Manufacturing

All Vision3 Lighting products are designed and manufactured in California's Central Valley using the following in-house machinery and processes:

All Vision3 Lighting products are designed and manufactured in California's Central Valley using the following in-house machinery and processes:

Our 30,000 sq. ft. brass and bronze metal casting facility is the largest brass and bronze jobbing foundry in the Western United States.

Our mold and pattern facility has state-of-the-art rapid prototyping design software and machinery. Patterns are made by skilled engineers and carried out by CNC machine operators.

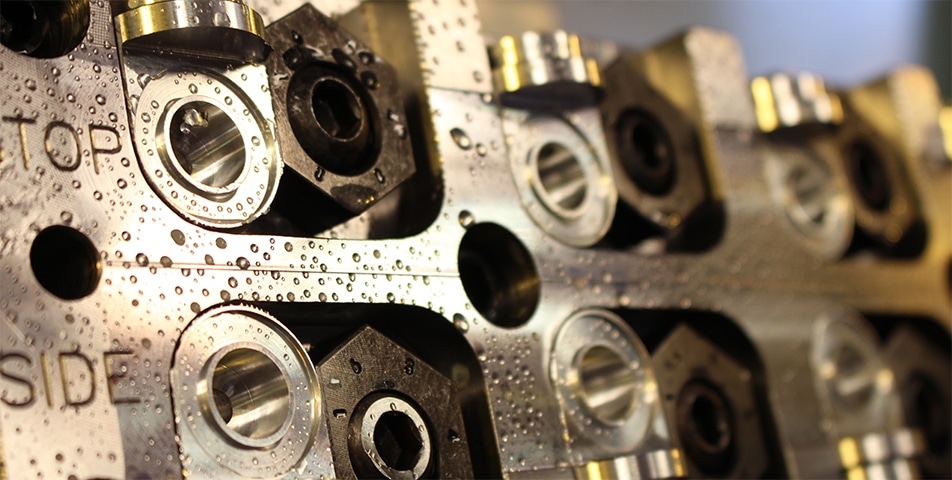

In-house CNC machining equipment produces precision-machined parts of various metal alloys including: aluminum, copper, brass, bronze, and stainless steel. Precision CNC metal stamping and fabricating equipment ensure that each product is impeccably produced from start to finish.

We use a batch powder coating system which allows us to offer more choices of TGIC polyester powder coat finishes. This includes fourteen standard colors, and virtually any custom color.

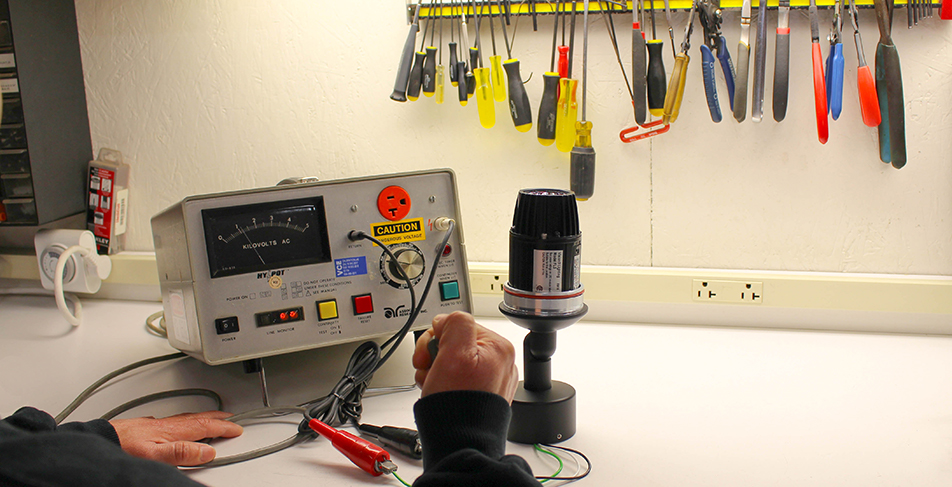

Every product is tested to meet U.S. and Canadian wet location safety standards. This includes heat testing on all fixtures, and vacuum testing for in-grade lights.